ENGINEERED PAINT BOOTHS & FINISHING SOLUTIONS. HISTORY OF EXCELLENCE.

RTT Engineered Solutions has emerged as a market leader in paint booths, powder booths, ovens, washers, AMU’s, and other finishing system components for use in the industrial, automotive, truck and large equipment, and woodworking markets. Focusing on a combination of impeccable customer service and product innovations, RTT has earned the respect and admiration of finishing applicators worldwide who rely on the most authoritative source to service their needs. We offer a full product line of performance-based paint booths that have been built with premium components and are delivered to you with all of the required hardware for quick and easy installation.

RTT Engineered Solutions Brings Precision and Practical Engineering to Finishing Solutions

Paint Booths for every industry

Our business is more than manufacturing quality products. We have united the most brilliant and gifted engineers from the industry, a creative product innovation team, exceptional customer service experts and strong leaders who remain committed to serving our distribution partners as they grow and their needs expand. RTT has always taken great pride and care in offering a select line of the most energy-efficient, high-quality and environmentally-optimized paint booths, also known as “spray booths”, and finishing systems to meet the broadest range of applications. From “floor model” bench paint booths to complete industrial finishing systems, RTT understands that every finishing operation has specific needs and requirements necessary to get the job done right. Over the last 23 years, RTT Engineered Solutions (formerly Col-Met Engineered Finishing Solutions) has provided the industry with high quality, reliable spray booths, powder booths, cure ovens and pre-treatment equipment.

RTT Engineered Solutions provides the highest quality industrial and automotive paint booths in the industry. Our finishing equipment and systems include paint booths, spray booths, powder coating booths, ovens, and more. We offer paint booths that are fitted for painting for small parts to large equipment such as semi-trucks. RTT also offers custom engineered paint booths to fit your finishing needs.

RTT’s high quality products include:

The RTT RP W-Series Filters offer the following benefits:

- Manufactured by RTT

- Superior Filtration Characteristics

- Maximum Holding Capacity

- Minimum Face Loading

- Compatible With Most Coatings

- Less Filter Change Outs

- Lower Operating Cost

The quality and workmanship of RTT spray booths allows us to be the only Spray Booth Manufacturer to offer a Five (5) Year Warranty* provided the customer utilizes our RTT high performance RP “W-Series” exhaust filters. These filters have been designed, tested and approved to provide superior paint particle separation while restricting the least amount of air flow in accordance with ASHRAE 52.1.

Paint Booths Manufactured by RTT Solutions

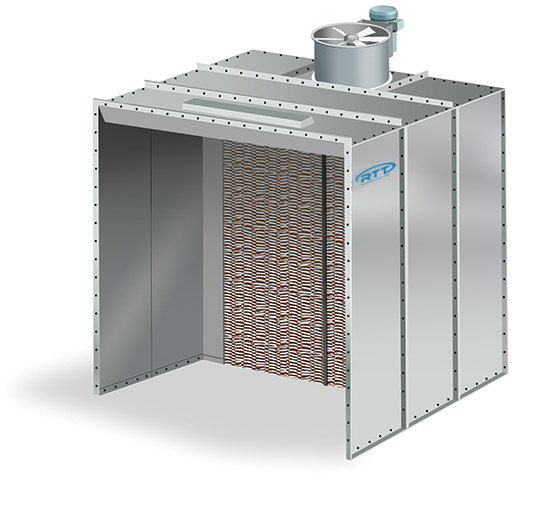

Open Front Paint Booths

Designed for both batch and conveyorized production systems, RTT’s Open Front Booths offer a safe environment for any type of finishing operation.

EZ Classic Crossdraft

Used for industrial, automotive and wood applications, the booth intakes air through filters in the product doors.

Downdraft Large Equipment Booth

By managing overspray more efficiently and reducing prep time, downdraft booths redirect fresh air through a filtered booth ceiling for an enhanced work environment.

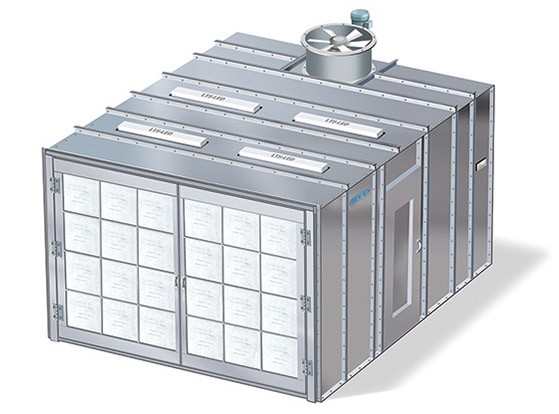

Enclosed Industrial Booths

Air flows in through the filtered double entry doors in the front of the booth, passes through the booth’s working area, and into the filtered exhaust chamber located in the rear of the booth.

EZ Modified Downdraft

Used for industrial, automotive and wood applications, the booth intakes fresh air from the cleaner upper levels of the shop through a filter bank located in the booth ceiling, near the product doors.

Crossdraft Large Equipment Booths

RTT’s large equipment spray booths are used in a wide variety of markets including aviation, rail, mining, truck, wind energy and other large-scale industrial finishing operations.

Open Front Bench Booths

RTT’s Open Front Bench Booths offer a safe environment for any type of finishing operation and allows easy paint application for small to medium sized parts.

EZ Pit Downdraft

The EZ Pit Downdraft spray booths are popular with automotive applications as they bring air from ceiling intake filters and disperse clean, fresh air from the top of the booth to the bottom.

Modified Downdraft Large Equipment Booths

RTT’s Large Equipment Spray Booths offer a safe and clean environment and are designed to meet or exceed all applicable OSHA and NFPA regulations.

Paint Mixing Rooms

RTT’s Paint Mix Rooms provide a controlled area for safely mixing paint. Easy to maintain and operate, the product line was developed to provide fast availability and simple installation.

EZ Side Downdraft

These booths are used for industrial, automotive and wood applications and serve as an economical solution for shops that are unable to install a pit type booth.

Side Downdraft Large Equipment Booths

With this configuration, there is no need to install a pit while still benefiting from the versatility, functionality and efficiency of a downdraft paint booth.

Powder Coating Booths Manufactured by RTT Solutions

Batch Powder Coating Booth

With an open front design, RTT’s batch powder coating spray booths are perfect for low volume powder applications.

Cartridge Batch Powder Coating Booth

Our Cartridge Batch Powder Coating Booths feature an open front (also known as open face) design and are ideal for small to mid-size powder applications.

Pass Through Powder Coating Booth

RTT offers a Pass Through Powder Coating Booth ideally suited for conveyorized coating applications looking for the most efficient system option.

Lab Powder Coating Booth

Extremely quiet and environmentally friendly, this booth is a perfect solution for operations with limited finishing space.

Long-Standing

You may call it great customer service. You may call it the best engineered finishing solutions around. We call it RTT integrity.

RTT operates ethically and honestly with strong leadership and strong principles, every single day. It’s our way of doing business. We consistently allocate the resources needed for continuous product design and manufacturing improvement to advance our engineering capabilities, to elevate our quality control standards, to ensure the best practices for our employees, and to encourage research and study of our craft.

No single person at RTT has all the answers. It is a collective effort that helps produce the solutions that will perfectly fit our customers’ needs. This group-think approach fosters a true team atmosphere among our concept developers, electrical engineers, equipment designers, sales engineers, service representatives and everyone else who works at RTT Engineered Solutions.

What Can We Help With?

Need advice on which paint booth is right for your space or assistance upgrading an existing system? Contact an RTT support representative today. We’re here for you anything you need!